Overview

Inspire Towers focus on the sustainable, offering flexible development and re-development of a brands appearance. Utilising a number of components that can be recycled multiple times in the creation of unique, modular, bespoke tower designs.

Inspire Towers can include a single centrally positioned tap, but equally can offer options such as off-set tap arrangements or even multitap configurations. The bar clamp can be uniquely integrated into the main tower chassis providing an innovative and cost saving solution.

Components

The components used in the construction of each system include a tap mounting block, a bar clamp screw mounting block and multi purpose cross brace.

Multiple cross braces would be used in each construction not only as an insulated mini python guide, but also a mounting point for the drip tray and fixing points for external claddings.

All three components would typically be manufactured as Zinc die castings in large numbers to keep the cost as low as possible.

Components

The components used in the construction of each system include a tap mounting block, a bar clamp screw mounting block and multi purpose cross brace.

Multiple cross braces would be used in each construction not only as an insulated mini python guide, but also a mounting point for the drip tray and fixing points for external claddings.

All three components would typically be manufactured as Zinc die castings in large numbers to keep the cost as low as possible.

Sheet Metal

The custom sheet metal parts are laser or waterjet cut from ether stainless steel or mild steel with a powder coat finish.

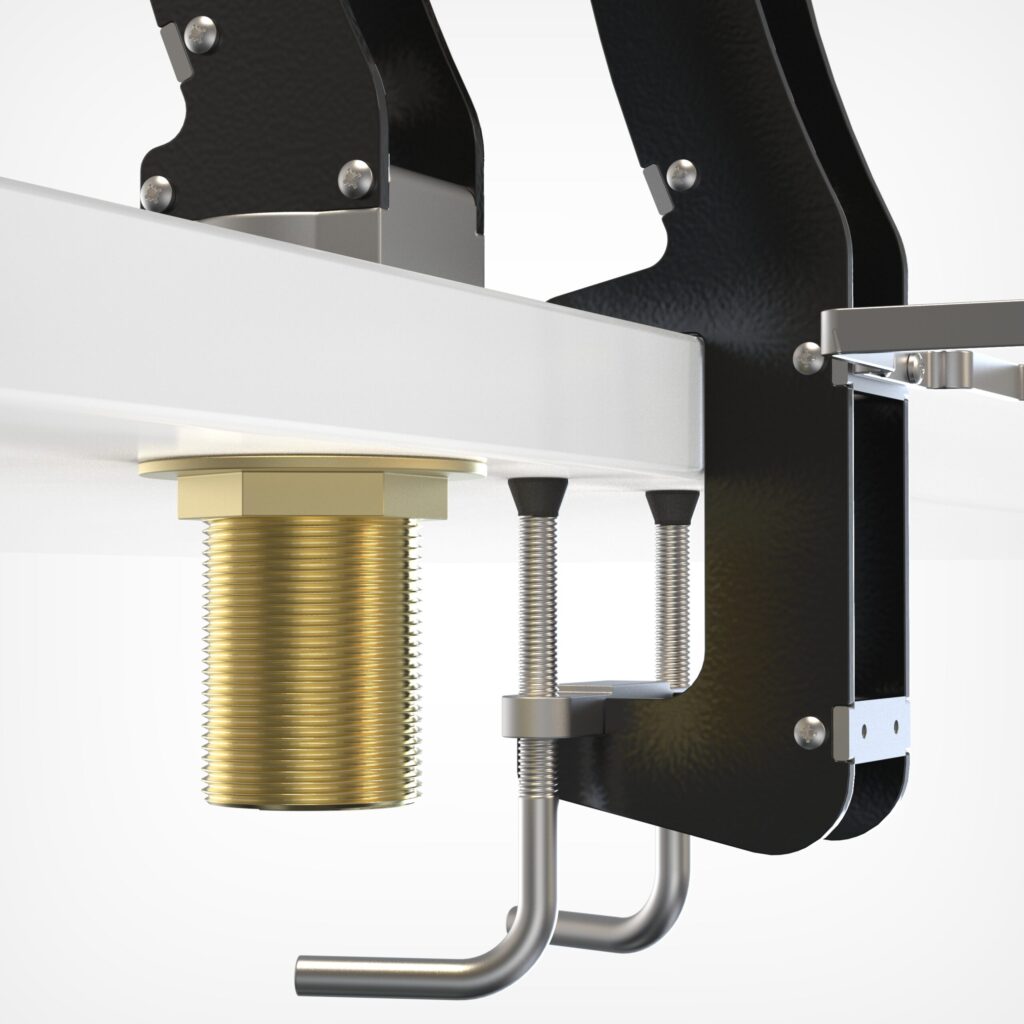

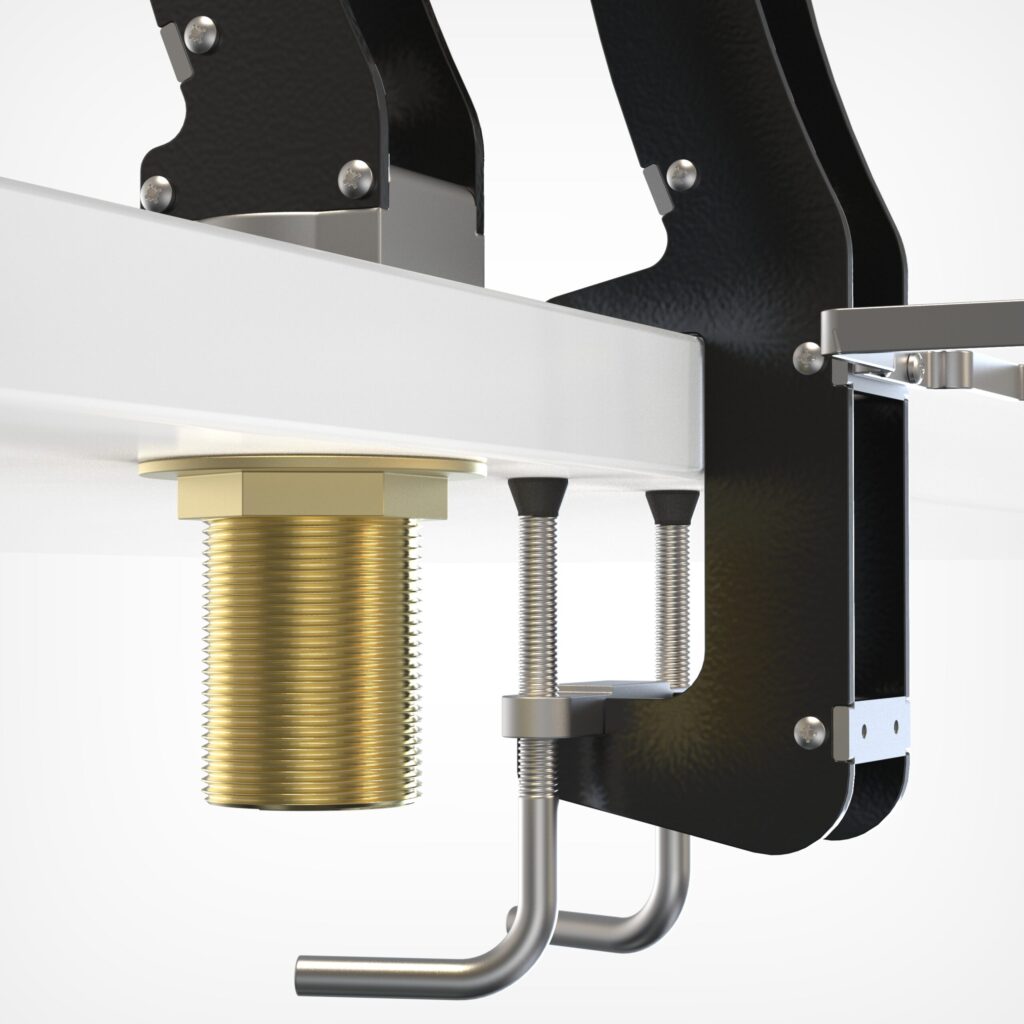

Bar Clamp

The integrated bar clamp used in this design allows you to change the size of the clamping foot depending on the footprint of the unit fitted to the system. You are also able to choose the exact position of the drip tray for maximum flexibility.

The rear cladding used on any design would be made cover the bar clamp as well. This will help to create a much cleaner and unbroken design.

Bar Clamp

The integrated bar clamp used in this design allows you to change the size of the clamping foot depending on the footprint of the unit fitted to the system. You are also able to choose the exact position of the drip tray for maximum flexibility.

The rear cladding used on any design would be made cover the bar clamp as well. This will help to create a much cleaner and unbroken design.

Off Set Tap

With the addition of an extra sheet metal component the tap can be mounted to the left or right of the main tower using a standard cross brace as a fixing point.

Multi Tap

With the addition of an extra sheet metal component, multiple taps can be fitted using the tap mounting block. This in turn facilitates opportunities for T-Bar and Bridge configurations.

Drip Tray

The unique design of the inspire chassis, allows for optimal height positioning of a standard 4” or 6” Square drip tray, alternatively it can be supplied with a more stylish ‘wrap-around’ option. This design saves space behind the bar, as well as allowing for simple, single-handed emptying of the Drip Tray, which is supported beneath from an integral support, as opposed to the traditional external Drip Tray mounting bracket.

Drip Tray

The unique design of the inspire chassis, allows for optimal height positioning of a standard 4” or 6” Square drip tray, alternatively it can be supplied with a more stylish ‘wrap-around’ option. This design saves space behind the bar, as well as allowing for simple, single-handed emptying of the Drip Tray, which is supported beneath from an integral support, as opposed to the traditional external Drip Tray mounting bracket.

Example

The integrated bar clamp used in this design allows you to change the size of the clamping foot depending on the footprint of the unit fitted to the system. You are also able to choose the exact position of the drip tray for maximum flexibility.

The rear cladding used on any design would be made cover the bar clamp as well. This will help to create a much cleaner and unbroken design.